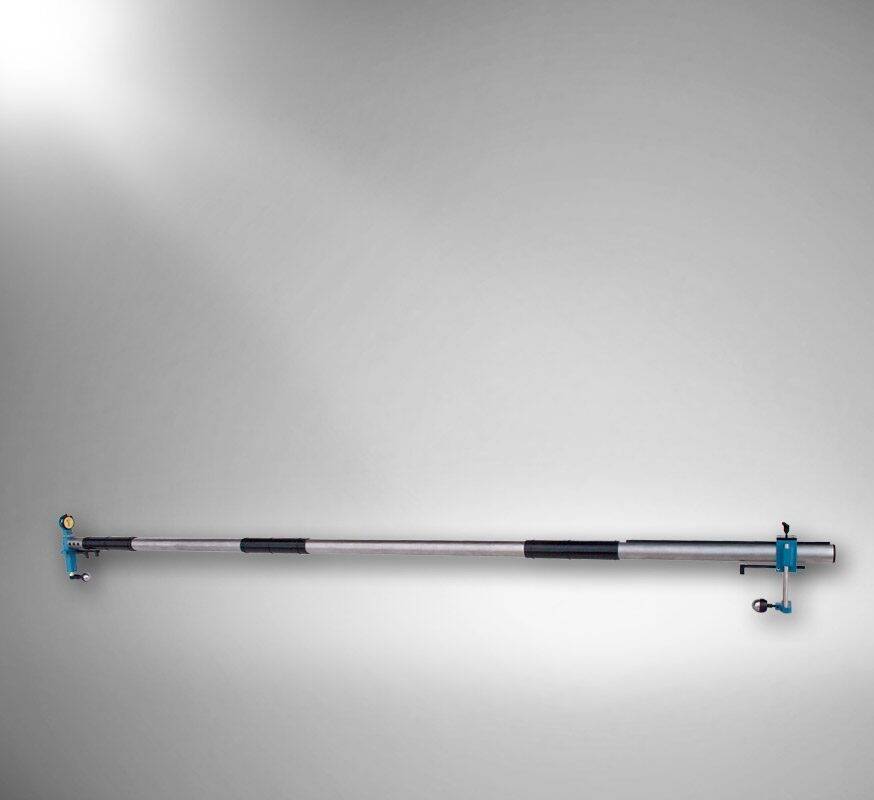

Dorsey is proud to introduce a new line of products in response to demand for large measuring diameters. Our new Ultra Large Diameter Gages have been designed to meet the largest, accurate measuring needs outside the capabilities of the traditional Dorsey Metrology gage family. This ultra large series measures large parts in the range of 60”, 1500 mm to 240”, 6000 mm, while maintaining accuracy, stability, and rigidity.

This line has come in response to several different industries, requesting measurement solutions for various functions. The product line meets the needs of even the most demanding user, with functionality including the inspection of large elements used in generators, turbines; aircraft engine housings, windmill parts, large bearings, large gears, large shaft lengths and ship building apparatus.

Dorsey's reputation as a leader in the field of large component measurement has put us in the position to bring together the largest selection of precise linear measurement movements, frame configurations, materials, contact point shapes, rest designs, and other accessories, as well as the knowledge of how to apply them to any large part inspection requirement. With our modular design it is possible to solve the inspection of almost any part configuration such as; inside/outside diameters, I.D./O.D. grooves, bearing raceways, conical and angular shapes.